Table of Contents

Oman’s factories want faster change, lower IT costs, and clearer control across plants and suppliers. Many are choosing Odoo migration services in Oman to replace rigid SAP setups with flexible Odoo ERP that fits real production needs. The focus is simple: quicker delivery, lower risk, and a system that grows with the shop floor.

Legacy SAP projects often stretch budgets and timelines for mid-market manufacturers. Odoo lowers license spend and shortens delivery for core workflows in production, inventory, and finance. Leaders get live dashboards for output, wastage, delays, and procurement, which support fast correction when bottlenecks appear.

Demand for open-source ERP is rising across automotive, packaging, and food processing units in Oman. Teams want systems that match changing line layouts, seasonal demand, and supplier shifts without long vendor cycles. With Odoo, they add only the modules they need, so they can track real growth.

SAP to Odoo Migration in Oman also unifies scattered data across MRP, sales, and accounting. Engineers stop juggling spreadsheets and exports and work from one production truth. Management sees accurate costs and on-time delivery metrics across warehouses and production cells.

Why Are Manufacturing Businesses Switching from SAP to Odoo in Oman?

SAP can feel costly and rigid when plants must adjust routings, work centers, or batch sizes quickly. Small changes often need long cycles, which slows improvement on fast-moving lines. That delay raises the total cost of ownership for teams under margin pressure.

Odoo’s open-source model offers greater freedom for workflows and factory reporting. Teams set up processes that match real layouts instead of forcing layouts to match software. This fit helps when launching new SKUs, adding shifts, or revising supplier contracts at short notice.

Odoo vs SAP for manufacturing also comes down to delivery speed and budget realism. Odoo projects start smaller, deliver value early, and expand with proven plant needs. This path lowers risk while building confidence across production and finance users.

SAP vs Odoo Comparison for Manufacturing ERP

| Feature | SAP ERP | Odoo ERP |

|---|---|---|

| Initial Cost | USD 50,000–120,000 | USD 8,000–25,000 |

| Annual Maintenance | 22% of license | 10–15% of setup |

| Customization Level | Limited | Highly configurable |

| Deployment Options | On-premise only | Cloud and on-premise |

| Implementation Time | 4–6 months | 4–8 weeks |

| License Type | Proprietary | Open-source |

| Integration Flexibility | Medium | Excellent |

How Does SAP to Odoo Migration in Oman Modernize Manufacturing Systems?

A planned migration upgrades production workflows and centralizes data for sharper control across plants and suppliers. Manufacturers achieve Manufacturing system modernization in Oman by replacing siloed tools with unified Odoo processes. Teams coordinate planning, purchasing, floor execution, and finance from one reliable source of truth.

Odoo acts as the hub that connects machines, teams, and partners through standard APIs and connectors.

With Odoo integration with manufacturing modules, planners trigger MRP runs and align purchasing with live demand. Supervisors see alerts on bottlenecks, rejects, and shortages, which support quick, practical action on shifts.

Real-time views replace delayed reports, so leaders can act while orders move through work centers. You track labor, materials, and downtime at the operation level, not the month-end level. That visibility drives faster cycle times, tighter costs, and better delivery performance for customers.

Key Advantages of Migrating to Odoo

- Unified dashboard for production and sales.

- Automated quality control workflows.

- Real-time inventory and order tracking.

- Simplified reporting and cost analytics.

Business Impact After Migration

| Process | Before (SAP Legacy) | After (Odoo ERP) | Improvement |

|---|---|---|---|

| Production Scheduling | Manual and delayed | Automated scheduling | 35% faster |

| Inventory Accuracy | 80–85% | 98–99% | +15% accuracy |

| Order Fulfillment Time | 3–4 days | 1–2 days | 50% faster |

| Data Visibility | Fragmented | Centralized | Improved decision-making |

What Are the Key Steps in SAP to Odoo Migration for Manufacturing?

A successful migration follows four focused phases that cover analysis, configuration, migration, and adoption. Each phase includes checkpoints, test runs, and sign-offs to reduce operational risk for the business.

The goal is a predictable cutover with measurable gains from the first production week.

Step 1 – Assessment and Data Analysis

We review SAP data structures, custom fields, and current process gaps across plants and warehouses. The team identifies which datasets move, which retire, and which require clean-up before import. This step sets the scope, risks, and acceptance criteria for a reliable handover. Use this data migration to Odoo guide for detailed checks and tools.

Step 2 – Module Mapping and Configuration

We map SAP modules like MRP, accounting, and HR to their Odoo equivalents with precise settings. Routing, work centers, BOMs, lots, and costing methods receive clear definitions for factory use. Security roles and approvals match your current controls, so teams keep accountability from day one.

Step 3 – Data Migration and Testing

We move master data, open transactions, and balances using ETL pipelines and Odoo import utilities. Multiple test cycles validate quantities, costs, and references against parallel reports. Any defects receive fixes before user acceptance, reducing noise during the cutover window.

Step 4 – Training and Go-Live

Hands-on training builds confidence for planners, storekeepers, and finance users in real scenarios. We run parallel testing to compare outcomes and adjust settings before final launch. Go-live occurs with a rollback plan and hypercare support to steady operations.

Migration Timeline and Deliverables

| Phase | Main Tasks | Duration (Weeks) | Deliverable |

|---|---|---|---|

| Planning | Requirement analysis | 1–2 | Migration plan |

| Data Preparation | Clean and map SAP data | 2 | Migration scripts |

| System Setup | Odoo configuration | 2–3 | Ready environment |

| Testing & Validation | UAT and bug fixes | 1 | Tested system |

| Go-Live & Support | Launch and monitor | 1 | Live Odoo ERP |

Which Odoo Modules Improve Manufacturing Efficiency the Most?

Manufacturers in Oman gain speed when core shop-floor work maps to the correct Odoo apps. With Odoo customization for manufacturing, teams cut double entry and keep work orders moving without delays. Strong Odoo integration with manufacturing modules links planning, purchasing, and execution for faster, cleaner decisions.

Return on investment grows when modules share data directly, not through exports or error-prone spreadsheets. Production leaders compare plan versus actual in real time and fix delays before orders miss slots. Procurement sets clear lead times and price breaks, then schedules deliveries to match live demand signals.

Finance trusts margins that link materials, labor, and overhead to every operation on the route. Supervisors track OEE, scrap, and changeovers from one dashboard, then act during the shift quickly. Plants keep control with light configuration, so future changes stay fast, safe, and predictable too.

Once modules run together, planners release work at the right pace and keep queues under control. Finance forecasts cash more accurately because stock, orders, and costs reconcile in the same system.

Key Modules to Focus On

- Manufacturing (MRP) – Automates work orders, routings, and capacity planning to cut waiting, rework, and idle time.

- Inventory – Tracks lots, bins, and cycle counts with barcodes that keep stock accurate across all locations.

- Purchase – Manages vendor price lists, lead times, and approvals so materials arrive when production needs them.

- Quality – Applies checkpoints, sampling plans, and nonconformance flows to cut defects and warranty claims.

- Accounting – Links costs to operations, so managers read true margins by product, line, and customer.

How Can the Right Partner Simplify SAP to Odoo Migration in Oman?

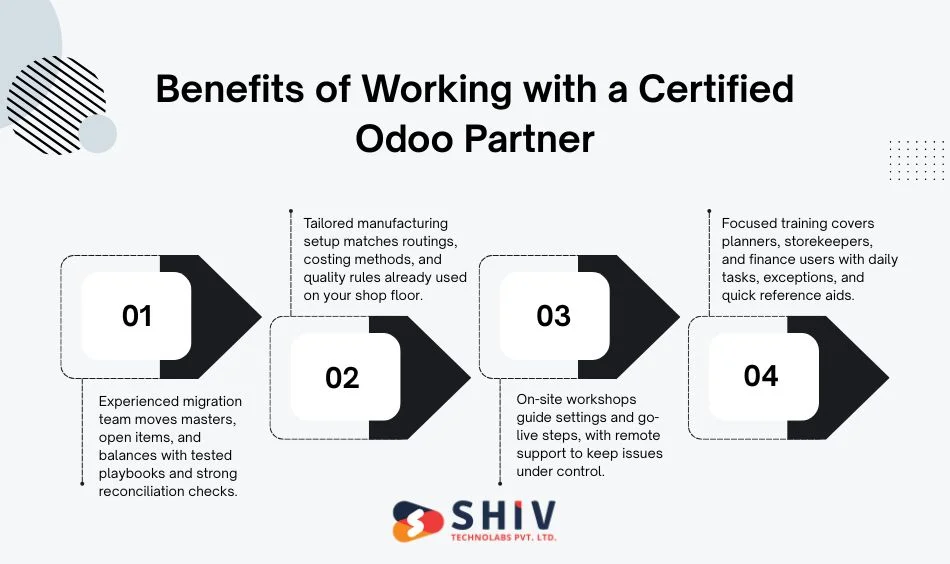

A proven Odoo implementation partner in Oman reduces risk and shortens every stage of your migration. Certified teams know SAP data models, factory workflows, and Odoo settings that fit real production lines. They protect the cutover window with repeatable methods, strong testing, and clear acceptance criteria agreed by stakeholders.

A good partner builds a roadmap that starts small, proves value, and scales in steady steps. They define roles, assign data owners, and set service levels for response and fix times. Your team receives clear guides and role-based training, so settings remain easy to manage in-house later.

Benefits of Working with a Certified Odoo Partner

- Experienced migration team moves masters, open items, and balances with tested playbooks and strong reconciliation checks.

- Tailored manufacturing setup matches routings, costing methods, and quality rules already used on your shop floor.

- On-site workshops guide settings and go-live steps, with remote support to keep issues under control.

- Focused training covers planners, storekeepers, and finance users with daily tasks, exceptions, and quick reference aids.

Choose a partner with factory case studies in Oman and clear support terms after launch. This approach protects budgets and keeps adoption on track during the first production weeks.

What Challenges Do Businesses Face During SAP to Odoo Migration in Oman?

Most hurdles come from messy data, user habits, and missing links between machines and business apps. Plan mock runs, UAT cycles, and staged launches to reduce downtime risk during the cutover period. Keep clear ownership, backups, and a rollback path to protect production while teams adopt new flows.

Common Migration Challenges and Solutions

| Challenge | Description | Practical Solution |

|---|---|---|

| Data Complexity | SAP tables are nested and dependent | Use field-level mapping templates and trial imports |

| User Adoption | Teams are used to SAP screens and flows | Run role-based Odoo workshops and quick reference guides |

| Integration Gaps | Missing connectors for machines or apps | Build lightweight API bridges and event hooks |

| Downtime Risk | Cutover overlaps with peak production | Schedule phased launches and keep a rollback plan |

How Does Odoo Support Long-Term Manufacturing Growth in Oman?

Odoo supports long-term growth by uniting production, inventory, purchasing, and accounting inside one connected platform. This approach drives manufacturing system modernization in Oman, with cleaner data and faster action during each shift. With SAP to Odoo Migration in Oman, teams add new capabilities as they grow, without heavy license commitments or slow delivery cycles.

Managers plan capacity with live numbers, so lines hit targets and planners catch shortages before they spread. Supervisors track throughput, scrap, and changeovers from one screen, then act while orders move through work centers. Finance reads true margins by product and line, because costs map directly to each operation and shift.

Growth-Focused Benefits

- Cloud scalability for multi-site factories

- Predictive maintenance and IoT readiness

- Integrated analytics dashboards

- Cost control with real-time data

ROI and Performance Metrics Post Migration

| Metric | Before Migration | After Migration | Result |

|---|---|---|---|

| System Downtime | 12 hours/month | 2 hours/month | 83% reduction |

| Production Efficiency | 70% | 92% | +22% |

| IT Maintenance Cost | USD 18,000/year | USD 7,500/year | 58% savings |

| Decision Reporting Time | 3 days | Same day | Instant analytics |

Migrate with Expert Guidance

Our team guides manufacturers through assessment, configuration, data migration, training, and steady support after launch. We design factory-ready setups for MRP, inventory, quality, and accounts, then validate results with parallel runs. Your staff receives role-based coaching and quick guides, so adoption stays smooth during the first production weeks.

Ask for a phased roadmap that proves value early, and grows with measured steps across plants and warehouses. We document settings, responsibilities, and acceptance checks, giving business and IT a clear handover and plan. This structure protects budgets and keeps performance on track while teams settle into new daily routines.

Conclusion – Future of Manufacturing ERP in Oman

Odoo gives manufacturers in Oman a practical path to faster cycles, lower IT spend, and clear reporting. By aligning planning, production, and finance in one system, teams sustain gains and improve delivery reliability. For guidance on ERP transformation, connect with Shiv Technolabs, a trusted Odoo migration company in Oman.

FAQs – SAP to Odoo Migration in Oman

Q1. How long does the SAP to Odoo migration take for manufacturing companies in Oman?

Most projects finish within six to eight weeks, based on data size, integrations, and training scope. Larger factories with many custom fields and reports may require extra time for testing and sign-off.

Q2. What are the key advantages of Odoo over SAP for manufacturers?

You cut license costs, start faster, and adjust workflows freely with a modular, open-source ERP platform. Manufacturing teams gain better scheduling, clearer inventory, and simpler reporting tied to actual shop-floor activity.

Q3. Can Odoo integrate with existing factory machinery or IoT systems?

Yes, teams connect PLCs and sensors through APIs, message queues, or gateways provided by equipment vendors. Odoo records readings, events, and alerts, then links them to lots, work orders, and maintenance plans.

Q4. What type of training is required after migration?

Plan role-based sessions for planners, storekeepers, and finance, focused on daily tasks and exceptions first. Follow with floor drills, quick-reference guides, and helpdesk support during the initial production weeks, too.

Q5. Which industries in Oman benefit the most from migration?

Automotive, packaging, and process manufacturers see quick wins from better scheduling, accurate stock, and live costing. Plants with frequent changeovers or seasonal demand benefit strongly from faster planning and reliable supplier coordination.