Table of Contents

Small manufacturers in the UK deal with tight production timelines, repeating orders, rising material costs, and constant pressure to deliver on time. Many teams still rely on spreadsheets, emails, and manual updates, which often leads to stock mistakes, late jobs, and unclear work status.

Manufacturing software helps small businesses fix these gaps. It brings production planning, stock control, order tracking, and shop floor tasks into one system. This makes it easier to see what materials are available, what jobs are running, and what needs attention.

In this guide, you will find the 10 best manufacturing software options for small businesses in the UK, along with the features that matter most for teams working with limited tools, small budgets, and fast-changing customer demands.

What Is Manufacturing Software?

Manufacturing software is a system that helps small businesses plan, run, and track their daily production work. It replaces scattered spreadsheets and manual updates with a central dashboard that shows materials, jobs, and deadlines in real time.

Most tools include key functions such as:

- BOM management

- Material planning (MRP)

- Stock tracking

- Work order creation

- Job scheduling

- Shop floor reporting

- Purchase management

Some systems also offer CRM, finance, and reporting features to support growing UK manufacturers.

For small teams, this software makes it easier to manage repeat orders, track raw materials, handle production changes, and maintain better control over job costs.

Why Small UK Manufacturers Need Manufacturing Software?

Small manufacturers face daily challenges that spreadsheets cannot handle. As orders grow, it becomes harder to track materials, work progress, and delivery dates manually. This is where manufacturing software helps.

1. Common Problems Without a System

- Stock levels become unreliable

- Teams lose time searching for job details

- Production stops due to missing materials

- Delivery dates change often

- Costs per job are unclear

- Quality checks are inconsistent

These issues reduce output and create delays that affect customers.

2. How Software Helps Small Teams

- Material planning becomes more accurate

- Work orders stay organised and visible

- Scheduling gets easier with clear job priorities

- Stock updates in real time

- Shop floor teams can log progress quickly

- Managers get clear reports on costs and output

For UK small businesses working with tight budgets and quick turnaround cycles, this level of control makes day-to-day production far smoother.

How to Choose the Right Manufacturing Software in UK?

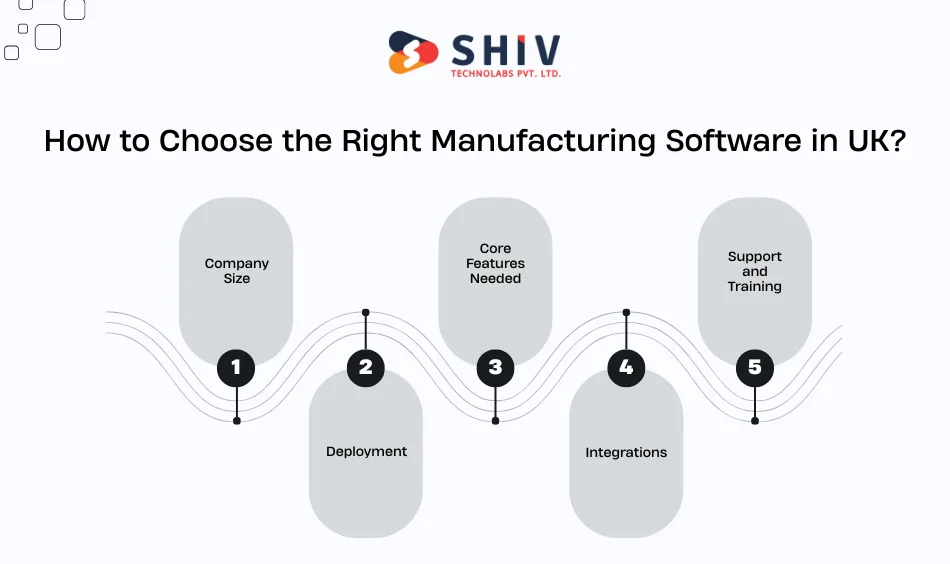

Picking the right software depends on your team size, production style, and daily workflow. Small UK manufacturers often need tools that are easy to set up, cloud-based, and affordable. Key factors to consider:

1. Company Size

- Micro teams (1–10 people) need simple tools with basic MRP and stock control.

- Small teams (10–50 people) need planning, scheduling, and shop floor features.

- Growing SMEs (50–200 people) may need ERP-style systems.

2. Deployment

Cloud systems suit UK small businesses because they require no hardware and come with easy monthly billing. Updates, support, and backups run automatically.

3. Core Features Needed

Look for tools that include:

- BOMs

- Material planning

- Work orders

- Scheduling

- Stock control

- Job costing

- Purchase management

These features help keep production smooth on busy days.

4. Integrations

Most UK companies need connections with:

- Xero

- Sage

- QuickBooks

- Shopify

- WooCommerce

Integrations help remove double-entry work.

5. Support and Training

Choose a system with strong UK support or local partners. This helps when you need quick guidance or industry-specific help.

Quick Comparison: Best Manufacturing Software for Small Businesses

Before reviewing each tool in detail, here is a quick way to understand what type of software fits different needs. This helps small UK manufacturers find the right match faster.

Best for Different Use Cases

- Simple MRP and stock control → MRPeasy, Katana

- Growing SME needing wider modules → Odoo, Business Central

- UK-based vendor with local support → Access FactoryMaster

- Manufacturers with service or repairs → Flowlens

- Job shops and make-to-order units → JobBOSS²

- Inventory-heavy production → Fishbowl

What Most Small Manufacturers Look For

- Clear material planning

- Real-time stock updates

- Easy work order tracking

- Simple shop floor reporting

- Quick setup and low monthly cost

- Good links to accounting tools

- Easy training for small teams

This summary gives a starting point, and the next section covers each software option in detail.

Top 10 Best Manufacturing Software for Small Businesses in the UK

1. MRPeasy

MRPeasy is one of the most popular choices for small manufacturers in the UK. It is built for teams with 5–200 people who need simple MRP, planning, and stock control without a heavy ERP setup.

Best For

Small manufacturers that need clear production planning, job tracking, and material management in one system.

Key Features

- Material planning (MRP)

- Real-time stock control

- Work orders and scheduling

- BOM and routing

- Shop floor reporting

- Purchase management

- Simple CRM and basic finance tools

Why UK Businesses Choose It

UK companies prefer MRPeasy because it is easy to start, cloud-based, and fits well with small and medium production units. It also integrates with Xero, QuickBooks, Shopify, and WooCommerce, which many UK manufacturers already use.

Pricing

It works on a monthly subscription model with different plan levels based on features and users.

2. Katana

Katana is a cloud-based manufacturing and inventory system built for small product makers. It focuses on giving a clear view of stock, materials, production stages, and sales orders—all in real time.

Best For

Small manufacturers that sell through eCommerce channels or handle batch-based production, custom items, or repeat orders.

Key Features

- Live inventory tracking

- Material planning (MRP)

- Work orders and scheduling

- BOM management

- Batch and expiry tracking

- Real-time shop floor visibility

- Purchase and supplier management

Why UK Businesses Choose It

Katana works very well with Shopify, WooCommerce, Amazon, and Etsy, which many UK small manufacturers rely on. It also integrates with Xero and QuickBooks, making it easy to manage stock and production without manual updates.

Pricing

Katana offers subscription-based plans with different feature levels for small teams, growing units, and multi-location businesses.

3. Odoo Manufacturing

Odoo Manufacturing is part of the larger Odoo ERP suite. It gives small UK manufacturers a flexible way to manage production, stock, sales, purchasing, and finances in one platform. It works well for growing teams that need more than just MRP.

Best For

Small and mid-size manufacturers that want all business functions—production, sales, stock, CRM, and accounting—inside one connected system.

Key Features

- MRP with BOMs and routing

- Work center and workstation control

- Scheduling and real-time production updates

- Quality checks and maintenance

- Inventory and warehouse operations

- Purchase automation

- Full integration with CRM, sales, and finance

Why UK Businesses Choose It

Odoo has many certified UK partners who help with setup, training, and industry-specific customisations and we are one of the certified Odoo developers for Manufacturing. The platform is modular, so UK manufacturers can start with only the features they need and add more as they grow.

Pricing

Odoo offers subscription pricing with add-on modules. Costs depend on the number of users and apps selected.

Must Read: Odoo ERP for Production Planning and Scheduling in Manufacturing

4. Microsoft Dynamics 365 Business Central

Business Central is a widely used ERP system for small and mid-sized manufacturers in the UK. It brings production, inventory, finance, and reporting into a single platform. Many UK companies prefer it because it is stable, scalable, and supported by a large network of local partners.

Best For

Small manufacturers need strong financial control along with production planning, stock tracking, and detailed reporting.

Key Features

- Production orders and scheduling

- Material planning (MRP)

- Inventory and warehouse management

- Sales and purchase workflows

- Job costing and reporting

- Power BI dashboards

- Strong accounting and finance tools

Why UK Businesses Choose It

Business Central fits well with UK accounting standards and integrates smoothly with Microsoft tools like Excel, Outlook, and Teams. It is also supported by many UK consultants who help manufacturers set up industry-specific workflows.

Pricing

Subscription pricing with different tiers based on modules and user roles. Add-ons and partner services may increase the budget.

5. Access FactoryMaster (Access Manufacturing)

Access FactoryMaster is a UK-based manufacturing system designed for small and mid-size manufacturers. It focuses on production planning, stock control, and traceability, and comes from a vendor with a strong UK presence.

Best For

UK manufacturers that want a trusted local provider with strong support, training, and links to accounting and warehousing.

Key Features

- MRP and production planning

- BOM and routing management

- Stock and warehouse control

- Works orders and scheduling

- Traceability and batch/lot tracking

- Quality and compliance tools

- Links to finance and other Access Group products

Why UK Businesses Choose It

Many UK manufacturers pick Access because they prefer a local team, onsite or remote training, and software that is already tuned to UK regulations and ways of working. It suits both make-to-order and make-to-stock environments.

Pricing

Pricing depends on modules, users, and implementation scope. It is usually sold through direct consultation rather than self-service signup.

6. Flowlens

Flowlens is a cloud-based system built for equipment, device, and machine manufacturers. It combines manufacturing, CRM, and service management in one tool, which is helpful if you also handle installs, repairs, or maintenance.

Best For

UK manufacturers that build equipment or devices and want to manage production, stock, sales, and after-sales service from one place.

Key Features

- MRP and stock control

- BOM and kit management

- Work orders and job tracking

- Service jobs, repairs, and maintenance

- CRM for leads, quotes, and orders

- Links with Xero, Sage, and QuickBooks

Why UK Businesses Choose It

Flowlens has a strong base in the UK and is well-suited to manufacturers who also run service teams. It helps keep product data, job history, and service records together so staff do not have to jump between different tools.

Pricing

Pricing is subscription-based and depends on features and user count. Quotes are usually shared after a short discovery call.

7. Manu Online

Manu Online is a cloud-based ERP system built for small and mid-size manufacturing companies. It focuses on automating everyday processes like order handling, materials control, and production planning so teams can do more with less admin work.

Best For

Small manufacturers that want a single cloud system for materials, production, sales, and invoicing, without a heavy on-premise setup.

Key Features

- MRP and real-time production planning

- BOMs, routing, and multi-step workflows

- Stock and warehouse management with traceability

- Work orders and time booking on jobs

- Sales order handling and invoicing

- Reporting and cost tracking

These features support both make-to-order and make-to-stock manufacturers that need clear control over orders, materials, and capacity.

Why UK Businesses Consider It

Although Manu Online is not limited to the UK, it is often listed as an option for small European and UK manufacturers that need cloud ERP with MRP, traceability, and automation. It suits teams that want to improve process flow without moving to a very complex enterprise system.

Pricing

Pricing is subscription-based and usually depends on the number of users and selected modules, with a focus on keeping the entry point affordable for small companies.

8. Fishbowl Manufacturing

Fishbowl Manufacturing is an inventory-focused system that adds strong manufacturing features on top of stock control. It is useful for small businesses that hold a lot of parts, raw materials, and finished goods across one or more locations.

Best For

Manufacturers that need tight control over inventory, work orders, and warehouse activity, especially when they already use accounting tools like QuickBooks or Xero.

Key Features

- Advanced inventory management

- Work orders and production planning

- BOM and sub-assembly management

- Multi-location stock tracking

- Barcode and warehouse tools

- Purchase and sales order management

These features help small manufacturers keep a clear visibility of what is in stock, what is reserved for jobs, and what needs to be ordered.

Why UK Businesses Consider It

Fishbowl suits UK companies that want strong warehouse and inventory control along with basic manufacturing features, without moving to a full enterprise ERP system. It is a good fit when inventory accuracy is a bigger pain than planning complexity.

Pricing

Fishbowl uses a licence + subscription model. Final cost depends on the number of users, modules, and any extra services.

9. JobBOSS²

JobBOSS² is a job shop management system designed for manufacturers that work with custom orders, small batches, or make-to-order production. It helps small teams plan jobs, track labour, manage materials, and deliver quotes based on accurate costs.

Best For

UK job shops, machine shops, fabrication units, and small engineering firms that need full visibility of quotes, work orders, schedules, and job costs.

Key Features

- Quote-to-job workflow

- Work orders and routing

- Scheduling and capacity control

- Labour time tracking

- Material planning and stock control

- Job costing and profitability reports

- Document management for drawings and specs

These features make JobBOSS² a strong choice for workshops where every job is different and precise cost tracking is essential.

Why UK Businesses Consider It

Many UK job shops choose JobBOSS² because it handles complex routing, labour tracking, and per-job costing better than general-purpose MRP tools. It helps teams keep work organised and maintain clear pricing for custom projects.

Pricing

Pricing works on a subscription model, with options for core modules and add-ons based on shop size and workflow needs.

10. SAP Business One

SAP Business One is an ERP system designed for small and mid-size businesses. It brings production, inventory, finance, sales, and reporting together in one platform. Many UK manufacturers pick it when they need strong financial control alongside manufacturing features.

Best For

Growing UK manufacturers that need detailed reporting, multi-warehouse control, and integrated finance within the same system as production planning.

Key Features

- Production orders and MRP

- Multi-level BOM management

- Stock and warehouse control

- Purchasing and supplier management

- Sales and customer workflows

- Costing and profitability analysis

- Built-in financial and accounting tools

These capabilities make it suitable for companies moving from basic MRP tools to a more structured ERP approach.

Why UK Businesses Consider It

SAP Business One is well supported in the UK through certified partners. It is often chosen by manufacturers that need strong compliance, audit readiness, multi-location stock, and tighter links between operations and finance.

Pricing

SAP Business One has licence and subscription options. Costs vary based on users, modules, and partner implementation.

Which Manufacturing Software Is Best for Your UK Small Business?

Every small manufacturer works differently, so the right system depends on your products, workflows, team size, and sales channels. Below is a quick guide to help you match your needs with the right software.

1. Best for Micro Teams (1–10 people)

- Katana → great for eCommerce + batch production

- MRPeasy → simple MRP with clear planning

- Flowlens → ideal if you also manage service work

These tools are easy to set up and require very little training.

2. Best for Small Growing Teams (10–50 people)

- MRPeasy → for planning, stock, and shop floor

- Manu Online → for end-to-end workflows

- Access FactoryMaster → strong UK support

These systems help reduce admin stress and keep production on track.

3. Best for SMEs with Multiple Departments (50–200 people)

- Odoo Manufacturing → modular ERP with many add-ons

- Business Central → strong finance + production

- SAP Business One → deeper reporting + multi-warehouse

These platforms work well when a company wants one system for production, finance, purchasing, sales, and reporting.

Implementation Roadmap for UK Small Manufacturers

A smooth rollout is just as important as choosing the right software. Small teams can avoid delays by following a clear step-by-step plan. This roadmap helps UK manufacturers get value from their system within the first 90 days.

Step 1: Map Your Current Workflow

Start by listing how orders move through your business—from sales to production to dispatch. This helps you set up the system correctly and avoid missing steps.

Step 2: Clean Your Product and BOM Data

Make sure your items, units of measure, BOMs, and materials are accurate. Clean data makes planning more reliable and reduces errors on the shop floor.

Step 3: Begin With Core Modules

Focus on a few essential areas first:

- Stock

- Purchasing

- Work orders

- Material planning (MRP)

Add other modules only when the team feels comfortable.

Step 4: Train Key Users

Choose a few team members to learn the system deeply. They will help everyone else adjust and maintain consistency in daily tasks.

Step 5: Add Shop Floor Reporting

Once planning and stock are stable, introduce shop floor tracking. This gives real-time visibility into job progress and helps managers make better decisions.

Step 6: Connect Accounting or eCommerce

After the core setup works smoothly, link tools like:

- Xero

- Sage

- QuickBooks

- Shopify

- WooCommerce

This removes manual entry and keeps the entire workflow connected.

Common Mistakes Small UK Manufacturers Make With Software

Even the best system can fail if it is set up incorrectly. Many small manufacturers run into the same issues during software selection and rollout.

1. Choosing a Tool That Doesn’t Fit Their Workflow

Some businesses pick a system based only on price or popularity. If it doesn’t match your production style—batch, custom, or make-to-stock—it creates confusion instead of clarity.

2. Ignoring Data Preparation

Incorrect BOMs, missing materials, and outdated item codes lead to planning errors. Clean and accurate data is essential for any MRP or ERP to work properly.

3. Adding Too Many Features at Once

Starting with every module can overwhelm small teams. A phased rollout reduces pressure and helps staff get used to the system step by step.

4. Not Training the Team Properly

When only one person understands the system, progress stops when they are unavailable. Shared training helps avoid bottlenecks.

5. Skipping Process Alignment

If your team keeps using old spreadsheets and habits, the new system cannot deliver results. Aligning daily tasks with the software is necessary for real-time updates.

6. No Clear Ownership

Every system needs a small internal team to handle settings, data updates, and support requests. Without this, workflows become messy.

Manufacturing Software Setup & Custom Solutions by Shiv Technolabs

Shiv Technolabs helps small and mid-size manufacturers set up the right digital systems for production, stock, and order handling. Our team supports UK businesses with custom software development, ERP setup, MRP configuration, and long-term technical support.

What We Offer

- Set up and customisation for Odoo Manufacturing

- MRP and ERP integration for growing units

- Custom modules for production, stock, and planning

- Data migration from spreadsheets or old tools

- Ongoing maintenance and feature updates

- API integrations (Xero, Sage, QuickBooks, Shopify, WooCommerce)

Why Manufacturers Choose Us

We work closely with production teams to shape software around real shop floor needs. This helps small businesses cut manual tasks, avoid errors, and keep production work on schedule.

Want to Upgrade Your Manufacturing Workflow?

Shiv Technolabs can help you pick the right system, set it up, and support your team through every step.

👉 Contact us to get a personalised plan for your manufacturing software setup.

Conclusion

Manufacturing software helps small UK businesses stay organised, reduce delays, and manage production with confidence. With the right system, teams get real-time control over materials, work orders, scheduling, and stock movement. This leads to fewer errors, faster delivery, and better decision-making.

The best choice depends on your size and workflow. Micro teams often start with tools like Katana, MRPeasy, or Flowlens, while growing manufacturers benefit from Odoo, Business Central, or SAP Business One. Job shops may prefer JobBOSS² for accurate costing and routing.

By following a structured rollout—clean data, simple modules first, and proper training—small UK manufacturers can get strong results in the first few weeks. With clear planning and steady adoption, the right software becomes a long-term asset.

FAQs – Manufacturing Software for Small Businesses in the UK

1. Which software is best for small manufacturers in the UK?

MRPeasy, Katana, and Flowlens are strong choices for small teams. Odoo, Business Central, and SAP Business One suit growing SMEs that need more modules.

2. What is the cheapest manufacturing software for small UK companies?

Tools like Katana and MRPeasy offer affordable entry plans for micro and small manufacturers. Pricing depends on users, features, and integrations.

3. Do small manufacturers need ERP or just MRP?

Micro and small teams often start with MRP tools for stock and planning. Companies with more departments or multi-warehouse operations may benefit from ERP systems.

4. How much does manufacturing software cost in the UK?

Most cloud systems charge monthly per user. Entry plans are the lowest, while advanced plans with shop floor, quality, or finance features cost more.

5. Can I use this software with Xero, Sage, or QuickBooks?

Yes. Many systems used in the UK—such as Katana, MRPeasy, Flowlens, and Business Central—offer direct integrations with these accounting tools.

6. Can small teams handle manufacturing software without IT support?

Yes. Modern cloud tools are easy to set up and do not require servers or special hardware. Most UK vendors also provide onboarding help.

7. Will this software work for custom or make-to-order jobs?

Systems like JobBOSS², Odoo, and MRPeasy support custom jobs, routing, labour tracking, and costing, making them suitable for job shops and engineering units.

8. How long does it take to fully implement a system?

Small teams can go live within a few weeks if the data is prepared. Full adoption with shop floor reporting usually takes 60–90 days.