Table of Contents

Most retail, ecommerce, FMCG, grocery, fashion, and manufacturing brands face frequent demand swings. Research across supply chain reports shows that 60% of companies deal with stockouts every month, while 30% carry excess stock worth 10–30% of their inventory value. Both issues weaken cash flow and create operational pressure.

Manual forecasting or spreadsheets cannot handle large SKU groups, multi-location stock, and fast-moving sales behavior. Even a small 5% prediction error can create thousands of dollars in lost sales or excess stock over a single quarter.

Demand forecasting software solves this by studying sales history, stock movement, supplier timelines, online activity, and store trends. With time-series and ML-based models, it predicts upcoming demand so planners can order the right quantity at the right time.

Companies that shift to forecasting systems often see 15–40% less excess stock and 20–50% fewer stockouts, making it a core part of modern inventory and supply chain planning.

How Demand Forecasting Software Works?

Demand forecasting software development studies past behavior and current signals to project future demand. It works by combining statistical models, machine learning methods, and real-time data inputs.

The process is built around identifying patterns that are difficult to detect manually, especially across large SKU groups and multiple sales channels.

1. Pattern Detection Through Historical Data

The system begins by analyzing sales history, stock movement, season cycles, store traffic, supplier timelines, and returns. This helps the software understand long-term behavior such as steady growth, decline, repeated seasonal peaks, or product-specific cycles.

2. Machine Learning Model Execution

Machine learning models study deeper relationships in the data. They read signals created by price changes, promotions, weather shifts, social triggers, and competitor activity. These models adjust continuously as new data arrives, allowing the system to react faster than static spreadsheet methods.

3. Short-Term Demand Sensing

Short-term demand sensing focuses on near-real-time signals. It reads POS activity, website traffic, order frequency, and sudden spikes that appear within hours or days. This helps brands deal with fast changes that traditional forecasting methods often miss.

4. Scenario Simulation

Many forecasting systems allow planners to run simulations. For example, planners can test how demand changes if a discount is applied, if a shipment is delayed, or if a new product is launched. These simulations support better decision-making during uncertain periods.

5. Continuous Forecast Refresh

The system refreshes forecasts automatically at fixed intervals—daily, weekly, or based on real-time updates. This ensures the predictions stay aligned with the latest customer and market behavior.

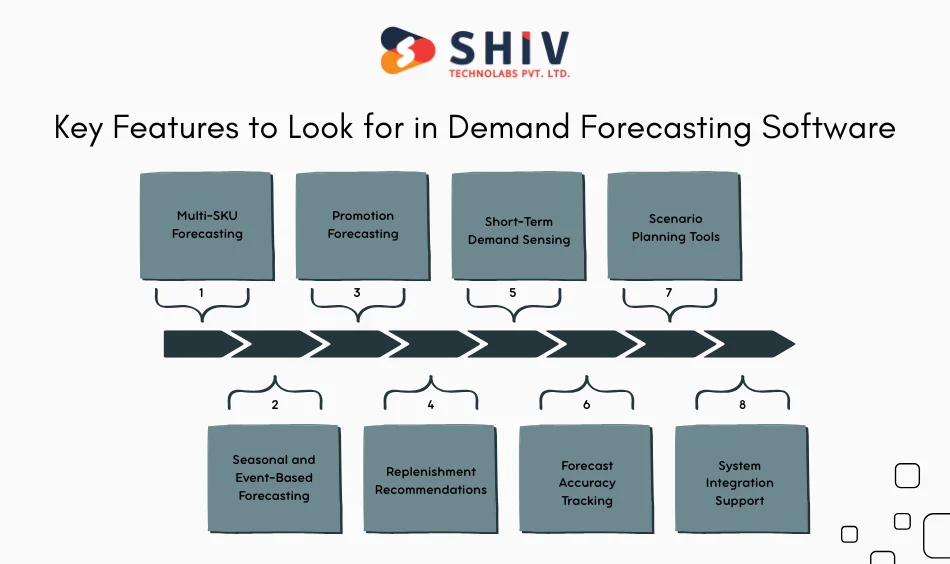

Key Features to Look for in Demand Forecasting Software

The strength of a forecasting system depends on the quality of its features. These features determine how clearly the software can read patterns, how fast it reacts to changes, and how well it supports supply chain and planning teams.

Below are the core features that matter most when selecting a forecasting platform.

1. Multi-SKU Forecasting

Businesses with large catalogs need forecasting that works across thousands of SKUs at once. The system must handle size, color, variant, pack size, and style combinations without slowing down. Accurate multi-SKU projections reduce both stockouts and excess stock.

2. Seasonal and Event-Based Forecasting

Many industries experience strong seasonal cycles or high-impact events such as holiday periods, back-to-school phases, or local festivals. Forecasting software detects these patterns automatically and adjusts the upcoming demand predictions based on past cycles.

3. Promotion Forecasting

Discounts, flash sales, loyalty campaigns, and influencer pushes can create sudden spikes. The software should be able to read how previous promotions affected demand and use those patterns to estimate future results. This helps planners avoid last-minute stock gaps.

4. Replenishment Recommendations

Beyond forecasting, advanced tools suggest replenishment quantities for warehouses and stores. These suggestions consider lead times, safety stock levels, warehouse limits, and expected order volume. This helps reduce manual guesswork.

5. Short-Term Demand Sensing

Short-term signals can shift quickly, especially in online channels. Demand sensing reads near real-time activity from POS and ecommerce sources to detect early spikes or drops. This is useful for fast-moving goods such as FMCG, grocery, and fashion.

6. Forecast Accuracy Tracking

A dependable system tracks its own accuracy. It compares predicted numbers with actual results and highlights gaps. This gives planners insights into which SKUs are stable and which require closer monitoring.

7. Scenario Planning Tools

Scenario tools allow planners to simulate conditions such as:

- a delay from a major supplier

- a shift in pricing

- a promotion across select categories

- an event-driven traffic increase

This supports better preparation and lowers operational risk.

8. System Integration Support

The forecasting tool must connect with ERP, POS, ecommerce, and warehouse systems to receive continuous and clean data. Strong integration keeps the forecasting engine aligned with real operational conditions.

Demand Forecasting Software Cost (Full Breakdown)

The cost of demand forecasting software depends on system depth, SKU volume, integration needs, and the level of machine learning involved. Businesses with large catalogs or multi-location setups usually spend more because their data structure and forecasting accuracy requirements are more complex.

Below is a clear breakdown of typical pricing patterns seen across global forecasting tools.

1. Subscription Cost Ranges

Most forecasting systems follow subscription-based pricing. The monthly cost varies based on data volume, number of users, and the level of forecasting models included. Smaller companies with a limited SKU set pay less, while enterprises with advanced ML-driven models pay significantly more.

2. Typical Monthly Pricing by Business Size

| Business Type | Estimated Monthly Cost | What’s Included |

| Small Business (up to ~2,000 SKUs) | $200 – $1,000 | Basic forecasting, seasonal pattern detection, and limited integrations |

| Mid-Size Business (2,000–20,000 SKUs) | $1,000 – $6,000 | Promotion forecasting, multi-location support, ERP/POS integrations |

| Enterprise (20,000+ SKUs) | $6,000 – $25,000+ | ML-based forecasting, real-time updates, scenario tools, and high data volume processing |

These numbers reflect typical SaaS and enterprise forecasting tools used in retail, ecommerce, FMCG, and manufacturing environments.

3. Implementation Costs

Apart from monthly subscription fees, most companies invest in setup and configuration. This includes data preparation, system integration, and model configuration. These steps ensure the forecasting engine receives clean, structured data.

a. Data Preparation

Cleaning and organizing historical data, fixing SKU errors, merging channels, and aligning product hierarchies can create extra costs.

Typical range: $1,000 – $10,000

b. System Integration

Connecting ERP, POS, ecommerce, and warehouse systems can vary based on data complexity.

Typical range:

- Standard integrations: $2,000 – $6,000

- Multi-location or custom systems: $7,000 – $20,000

c. Custom Model Setup

Industries with unusual patterns—such as perishable goods, rapid stock cycles, or region-specific demand—often require custom ML models.

Typical range: $5,000 – $30,000+

4. Additional Cost Factors

a. Training and User Onboarding

Some platforms charge for user training sessions, especially if the system includes advanced dashboards or scenario tools.

b. Forecast Accuracy Monitoring

Ongoing model tuning and performance tracking may incur extra cost if the vendor offers specialized analytics.

c. Alert and Exception Setup

Setting up alerts for stockouts, sharp demand rises, or supply delays might fall under custom configuration.

Setup and Implementation — What You Need Before Going Live

The success of demand forecasting software depends on how well the setup is executed. Forecast quality improves when historical data is clean, integrations are stable, and operational rules are aligned with real-world processes.

Below is a clear view of the key steps involved in preparing and implementing a forecasting system.

1. Pre-Setup Requirements

Before activating the forecasting engine, businesses need a few important inputs in place.

a. Clean Sales and Inventory Data

Historical sales, stock movement logs, and returns must be organized. Gaps, duplicate entries, and mismatched product codes can reduce accuracy. Most forecasting models perform well when at least 12–24 months of structured data is available.

b. Supplier Lead Time Information

Lead times play a major role in replenishment planning. Accurate lead time data helps the system calculate when to order and how much safety stock is needed.

c. Channel and Location Data

Brands that operate across stores, warehouses, and ecommerce channels must have complete records for each location. This helps the forecasting engine detect location-specific trends.

2. Implementation Steps

Once the data foundation is ready, the setup begins. Most companies follow the steps below.

a. Data Mapping

Product categories, SKUs, locations, and historical records are aligned with the system’s structure. This prevents mismatches during model training.

b. Integration Setup

The software connects with ERP, POS, eCommerce, and warehouse systems. Automated data flow ensures the forecasting engine receives continuous updates.

c. Model Configuration

The forecasting system is configured based on the business structure. This includes:

- product hierarchy

- season patterns

- safety stock rules

- warehouse and store grouping

- lead time profiles

These settings help the model understand how each part of the business functions.

d. Initial Forecast Run

The system runs the first round of predictions using historical data. Planning teams review these outputs to confirm if the trends align with known behavior.

e. Accuracy Review

The software compares predicted values against recent sales to calculate accuracy. If the model needs refinement, adjustments are made before full deployment.

3. Go-Live Checklist

Before switching to the live environment, teams verify:

- data refresh timing

- integration stability

- user access rights

- dashboard visibility

- approval workflows

These steps help ensure a smooth transition and stronger adoption across departments.

Use Cases Across Industries

Demand forecasting software supports a wide range of industries, each with its own challenges and patterns. The software adapts to these different environments by studying category-specific behavior, stock cycles, and customer activity. Below are the most common real-world use cases.

1. Retail

Retail brands manage both store traffic and online orders. Forecasting software helps them project demand for each SKU, plan replenishment for multiple locations, and prepare for seasonal peaks. It also supports better stock allocation during sale events or regional promotions.

2. Ecommerce and D2C

Online demand shifts quickly due to promotions, influencer activity, or sudden traffic spikes. Forecasting software predicts order surges, identifies fast-moving SKUs, and prepares warehouse teams for packing and shipping volume. It helps prevent stockouts during flash sales or campaign periods.

3. FMCG and CPG

Fast-moving goods require frequent restocking. Forecasting software captures daily and weekly consumption patterns, trade promotion impact, and short shelf-life behavior. This helps distributors and brands maintain a steady supply without building unnecessary surplus.

4. Grocery and Essentials

Grocery chains depend on accurate short-term forecasting because demand changes daily. The software predicts the needs of perishable items, reduces waste, and prepares stock for weekends or holiday periods. Location-specific forecasting is especially important due to varied buying patterns.

5. Fashion and Apparel

Fashion demand is unpredictable because styles, sizes, and colors shift quickly. Forecasting software helps brands project demand across variants, plan seasonal transitions, and avoid overbuying slow sellers. It also supports online and offline allocation during peak events.

6. Manufacturing and Wholesale

Manufacturers work with long production cycles and supplier constraints. Forecasting software predicts upcoming bulk requirements, helps schedule production, and aligns raw material procurement with expected demand. This reduces delays and improves delivery reliability.

Problems Demand Forecasting Software Solves

Demand forecasting software plays a critical role in addressing issues that directly impact revenue, stock health, and supply chain performance. Below are the common problems it helps reduce or eliminate.

1. Frequent Stockouts

Stockouts occur when demand rises unexpectedly or when planners underestimate future needs. Forecasting software detects early demand shifts and helps maintain enough stock to meet upcoming orders, especially for fast-moving SKUs.

2. Excess Inventory

Carrying excess stock ties up working capital and increases storage costs. Forecasting software highlights slow-moving items, seasonal dips, and declining patterns so planners can reduce unnecessary replenishment and cut excess stock.

3. Dead Stock Accumulation

Items that no longer sell create long-term losses. Forecasting systems identify products with downward trends and provide early warnings, allowing teams to adjust pricing, run small promotions, or reduce future orders.

4. Inaccurate Manual Forecasting

Spreadsheet-based forecasting struggles with large SKU sets, multi-location data, and irregular patterns. Forecasting software processes thousands of data points at once and produces consistent predictions with lower error margins.

5. Poor Replenishment Timing

Wrong timing in procurement leads to delayed orders or overfilled warehouses. Forecasting software uses lead time data, safety stock rules, and predicted demand to recommend the right replenishment window.

6. Sudden Short-Term Demand Spikes

Promotions, weather conditions, viral trends, or local events can cause rapid increases in demand. Short-term sensing tools detect these changes early, reducing the risk of missing sales during demand surges.

7. Unstable Supply Chain Visibility

When multiple locations, channels, or warehouses are involved, stock visibility becomes complicated. Forecasting software consolidates data and offers a clearer view of upcoming needs across the entire network.

The Role of AI and ML in Modern Forecasting

Artificial intelligence and machine learning have reshaped how forecasting systems operate. Traditional statistical methods alone cannot handle the volume, speed, or complexity of today’s sales and inventory patterns. AI and ML add the flexibility and precision needed to analyze large datasets and react to rapid changes in customer behavior. Below are the key ways these technologies strengthen forecasting.

1. Learning from Complex Data

AI models can process large datasets that include sales logs, returns, website activity, store traffic, and supplier timelines. Instead of relying on one pattern, ML models study multiple signals at once and pick up relationships that human planners or basic formulas often miss.

2. Adapting to New Behavior

AI-driven models adjust automatically when new patterns appear. For example, changes caused by price shifts, competitor actions, weather events, or viral trends can be detected quickly. This helps planners correct stock levels before demand changes become costly.

3. Short-Term Demand Sensing

ML models improve short-term sensing by scanning POS data, online traffic, and order frequency in near real time. This helps brands respond faster during sudden increases in demand, especially for fast-moving goods in FMCG, grocery, or fashion.

4. Scenario Evaluation

AI models can run simulations that test how demand changes under different conditions. This includes new product launches, promotion campaigns, or supply delays. These simulations support better planning during uncertain periods.

5. Higher Forecast Accuracy

Because ML models learn continuously from new data, accuracy improves over time. This results in stronger predictions for seasonal products, high-variation SKUs, and items with unpredictable demand behavior.

ROI of Demand Forecasting Software

Demand forecasting software delivers measurable financial and operational returns. These returns come from better inventory decisions, reduced waste, stable supply rhythm, and more accurate planning. Below are the key areas where businesses typically see improvement after adopting forecasting tools.

1. Lower Stockout-Related Losses

Stockouts lead to immediate revenue loss and often push customers toward competitors. With clearer visibility into upcoming demand, brands can maintain the right stock levels. Many companies report 20–50% fewer stockouts within the first year of using forecasting systems.

2. Reduction in Excess Stock

Excess stock ties up working capital and occupies warehouse space. Improved forecasting accuracy helps reduce unnecessary replenishment. Studies across retail and FMCG sectors show a 15–40% reduction in excess stock after switching from manual forecasting to ML-driven systems.

3. Better Inventory Turnover

Forecasting software helps maintain healthier stock rotation and reduces the number of slow-moving items. This results in higher inventory turnover, improved cash flow, and fewer long-term storage costs.

4. More Accurate Procurement Decisions

With forecast-driven replenishment suggestions, teams can order at the right time and in the right quantity. This lowers emergency orders, reduces air freight costs, and improves supplier coordination—all of which contribute to financial savings.

5. Higher Team Productivity

Automated forecasting removes hours of manual work spent preparing spreadsheets, cleaning data, and updating stock projections. Planning teams can focus on analysis and decision-making instead of mechanical tasks.

6. Improved Customer Satisfaction

Stable stock availability and faster fulfillment help brands maintain higher customer satisfaction scores. Forecasting clarity allows businesses to respond to demand spikes without delays, strengthening customer trust.

Why Businesses Partner with Shiv Technolabs

Demand forecasting works best when the system is configured correctly and connected to every part of the supply chain.

Shiv Technolabs helps businesses set up forecasting solutions that match their data structure, product hierarchy, and operational flow. Our digital transformation services focus on accuracy, model stability, and long-term scalability.

We support companies by providing:

- ML-driven forecasting models tailored to their industry and SKU structure.

- Clean and organized data pipelines that help the forecasting engine read patterns clearly.

- End-to-end system integration across ERP, POS, ecommerce stores, and warehouse platforms.

- Custom dashboards and reporting tools that give planners a clear view of upcoming demand.

- Scenario planning features for launches, promotions, and supply delays.

- Automated workflows that reduce manual forecasting effort and improve team productivity.

- Support for multi-location and multi-channel operations, helping brands manage complex stock networks.

Brands across retail, FMCG, D2C, fashion, grocery, and manufacturing contact Shiv Technolabs because we build forecasting setups that are dependable, scalable, and aligned with their real-world processes.

Conclusion

Demand forecasting software has become a central part of modern supply chain and inventory planning. As product catalogs expand and sales channels diversify, manual forecasting methods cannot maintain the accuracy required for stable business performance. Software-driven forecasting brings clarity by reading sales patterns, seasonal behavior, and short-term demand signals with higher precision.

With the help of machine learning and structured data, planners can make better decisions for replenishment, procurement, and production. This reduces stockouts, lowers excess stock, improves inventory turnover, and strengthens overall operational stability. Whether a business operates in retail, ecommerce, FMCG, grocery, fashion, or manufacturing, forecasting software provides the foundation for predictable and controlled stock movement.

Companies that invest in the right forecasting solution not only improve planning accuracy but also build a stronger path for long-term growth. When paired with the right implementation partner, the system becomes a reliable asset for daily and future decisions.

FAQs

1. How does demand forecasting software calculate upcoming demand?

The software studies sales history, stock movement, seasonal cycles, and short-term customer activity. Machine learning models scan large datasets to identify repeating patterns and sudden shifts. These insights are processed into daily, weekly, or monthly predictions that help planners make accurate decisions.

2. How much data is required for accurate demand forecasting?

Most systems perform well with 12–24 months of clean, structured data. The more stable the data, the stronger the predictions. Businesses with frequent SKU changes or seasonal cycles may require longer history for the model to read patterns correctly.

3. Does demand forecasting work for new products with no sales history?

Yes. In such cases, the system uses similar product categories, past launches, price behavior, and early customer signals to estimate demand. Over time, the model improves accuracy as new data becomes available.

4. Can forecasting software reduce stockouts?

Yes. By reading early demand signals, the system helps maintain balanced stock across stores, warehouses, and online channels. Brands typically observe 20–50% fewer stockouts after adopting automated forecasting.

5. How does the software help prevent excess stock and dead stock?

Forecasting models highlight declining SKUs, seasonal dips, and slow-moving items. This helps planners adjust purchase quantities and avoid over-ordering. Many businesses experience a 15–40% reduction in excess stock after switching from manual planning.

6. What is the usual cost of demand forecasting software?

Costs vary by business size and SKU count. Small businesses may spend $200–$1,000 per month, mid-size companies $1,000–$6,000, and larger enterprises $6,000–$25,000 or more. Implementation costs depend on data quality and integration needs.

7. How long does it take to implement a forecasting system?

Implementation can take a few weeks to a few months. The timeline depends on data preparation, integration complexity, and model configuration requirements. Clean data and stable integrations help shorten this process.

8. Does forecasting software support multiple locations and channels?

Yes. Most systems handle multi-location warehouses, retail stores, ecommerce channels, and regional distribution. The software can analyze each location independently while maintaining a unified forecast for the entire network.

9. Can AI forecasting handle sudden demand spikes from promotions?

AI models can read short-term signals from POS systems, online traffic, and past promotion results. These insights help the system react faster during high-activity periods, reducing the risk of missing sales during spikes.

10. How does demand sensing differ from standard forecasting?

Demand sensing focuses on short-term signals such as POS activity, order frequency, and online traffic. Standard forecasting reads long-term and seasonal patterns. Both methods work together to maintain forecast accuracy across different time windows.

11. What makes Shiv Technolabs a good partner for forecasting projects?

Shiv Technolabs works with ML-driven models, data engineering pipelines, and end-to-end system integration. Our team aligns product structures, cleans historical data, and configures models that match each brand’s operational flow. This leads to stable and reliable forecasting outcomes.

12. Can Shiv Technolabs build custom forecasting dashboards and scenarios?

Yes. We design dashboards that highlight key demand signals, forecast accuracy, SKU trends, and location insights. We also build scenario tools that help planners test multiple conditions—such as promotions, price changes, or supply delays—before making decisions.